Sandwich Panel Container

- 26 February 2024

What is Sandwich Panel Container?

The type of container in which sandwich panels are used in the wall and roof system is called sandwich panel container.

How is Sandwich Panel Container Production Done?

Sandwich panel containers, produced in modern facilities where new generation technologies are used, stand out with their superiority in quality and ergonomics. The production process first begins with the shaping of the lower and upper chassis on the machine line. Chassis made of steel metals are used with special thickness steels for container structure safety. Stainless steel metals are made ready for painting by bending, cutting and drilling bolt holes on the machine line. Sandwich panel containers are painted with the painting technology used in the automotive industry and become ready for assembly.

Special Wicks That Increase Sandwich Panel Container Insulation

The structure, whose lower and upper chassis are connected to the carrier poles with a bolt-nut and plug-in system, is ready for the arrangement of sandwich panels. Special EPDM wick is placed at the junction of sandwich panels and steel metals. This wick makes the combination of metals and panels healthy and also increases insulation. Afterwards, the sandwich panels are arranged.

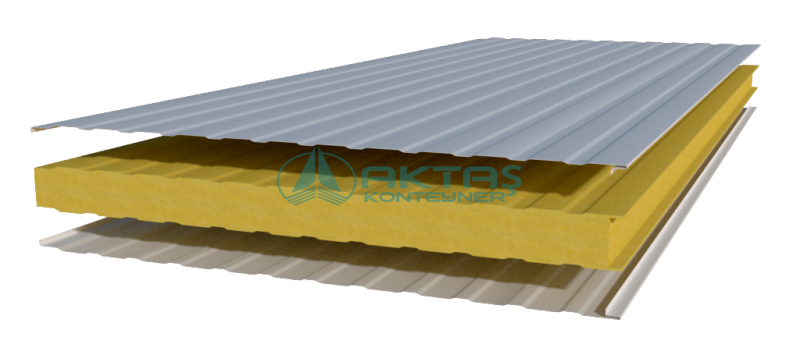

How Are Container Sandwich Panels Made?

In the production of sandwich panel container wall and roof panels, EPS foam is used between metal sheets in both directions as standard. Sandwich panels using these high-density foams are 5 cm thick on the walls and 12.5 cm thick on the roof. Mineral wool (rock wool) filling material can also be used between metal sheets for higher insulation expectations.

Arrangement of Sandwich Panels on Container Chassis

The 125 mm thick sandwich panel used on the upper roof is arranged on the chassis and locked with the clamp system. With the special clamp connection system, leakage and air intake are eliminated. Wall panels are pre-prepared to a length specific to the container height. 125 cm wide sandwich panels are assembled by connecting them to the upper and lower chassis interlockingly. During the installation, the PVC double-glazed windows on the front and the special door are also installed. If there is one at the back, the ventilation window in the models with a toilet is installed at this stage.

Reinforced Floor Sandwich Panel in Container

Sandwich panel container floor is prepared with the densest arrangement of high galvanized profiles between the sub-chassis. Instead of welding, which would put the ground at risk, bolt-nut and plug-in connections are used in the chassis connection of the profiles. The floor is covered with fiber cement boards or optionally playwood material placement. A special thickness of mineflo is laid on top of these and the floor is made ready for use.

Weldless New Generation Technology Sandwich

In Panel Container: The new generation technology developed with the expertise in the sector has been brought together with sandwich panel container construction. The new technology developed in the R&D and P&D processes has reflected superiority in the production of container structures. Applications such as resource use, uninsulated trapezoidal sheet metal panels and paneling in traditional container production have been terminated. New generation sandwich panel containers continue to provide savings to construction companies and individual residential users as they are used.

Specially designed sandwich panel container manufacturing is carried out with a weldless system on modern lines equipped with new generation technologies. In the new production, welding has been replaced by the use of bolts and nuts.

Where is Sandwich Panel Container Used?

Sandwich panel containers, which offer safe, long-lasting and ergonomic practical living spaces, are used wherever ready-made structures are needed. Office containers are among the most common places of use, especially in construction sites and commercial areas. In addition, container houses are preferred in the housing sector with their economical prices and ready-made construction concept.

Sandwich Panel Container Models Sandwich panel container models attract attention with their ergonomics and comfort. They offer the best ergonomics for interior use depending on the size of the building. Designed with experience-based expertise, sandwich panel container models offer a comfortable living space to their users.

Sandwich Panel Container Increases Efficiency on Construction Sites Sandwich panel containers increase efficiency by offering the comfort demanded by workers in construction site construction groups. They provide comfortable dormitories and dining halls for workers in summer and winter, in hot and cold weather, in rain or dust. The productivity of workers using Karmod sandwich panel containers increases.

2.30×5.95 or 3×7 Sandwich Panel Container Models Sandwich panel containers are manufactured in various plans in 2.30×5.95 or 3×7 models. These dimensions are prepared as single units and can be placed side by side or on top of each other to create larger structures when desired. Each model provides the same ergonomics and comfort when creating large structures from single units.

Sandwich Panel Counter

Specification It is important to consider the following technical details when preparing or checking sandwich panel container specifications that reflect construction quality.